UL94

Laboratory > Thermal

| Characteristics and notes on self-extinguishing materials | |

Norm UL-94 One of the typical characteristics of all plastics is their low resistance to flames. The demand for self-extinguishing materials is continuously increasing due to the need to offer higher levels of safety in everyday and work environments and also for the construction of technical and mechanical parts. The behavior in the presence of fire of plastic materials can be examined in different ways, depending on the standards we wish to take into consideration, either by examining the behavior in the applied tests that considering the possible effects of fire extinguishers or additives whose Help is to delay the spread of fire. Generally these additives are compounds that are based on halogen phosphors. The additives give the plastic a self-extinguishing power, but when they burn, they emit highly toxic fumes whose opacity makes their escape very difficult and dangerous. In addition, the fumes emitted are highly corrosive and can damage and / or disable the electronic alarm and the relief devices. The simple "resistance to the flames", therefore, has lost its importance due to the negative effects of the smoke emitted during the burning: density of exhaled fumes, its toxicity or oxygen limit. Experience has shown that in most cases a self-extinguishing plastic material that emits fumes and toxic gases is more dangerous than an unmodified material whose self-extinguishing power is low but does not emit dangerous fumes. Different studies about accidents caused by fire in public places, underground rail systems, etc. They have shown that fumes and toxic gases are the main causes of danger for people. In addition, experience has shown that in some fire extinguishers, polybromides emit dangerous and highly toxic dioxins and furans. When you have to choose a plastic material, we must also evaluate the existing laws, the type of product, its placement in the environment, the content of halides or fire extinguishing gases and its effect on the polymer. |  |

| Burning capacity UL-94 | |

The test methods highlighted by the American Guarantor Laboratories are usually the most used to define the burning capacity of a plastic polymer. It must be specified if the material has been modified with a fire extinguisher or if it does not have halogens. The first HB test determines the non-flammability of a polymer. Tests V.0, V.1, V.2 determine the degree of self-extinction of a polymer. | |

| UL 94 HB | |

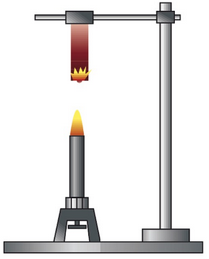

| This test measures the burning time of a horizontally fixed plastic sample (the thickness is specified in the test) after it has been contacted with the flame of a Bunsen burner for 30 seconds. According to the U.L. 94 HB (Horizontal Burning) the material is classified H.B. when a sample of a thickness of 3 mm is burned at a maximum speed of 76 mm / minute. | |

UL 94 V.0 - V.1 - V.2 | |

| This test measures the burning time of a vertically fixed plastic sample (the thickness is specified in the test) after it has been contacted with the flame of a Bunsen burner for 10 seconds. According to U.L. 94 (Vertical Burning) the material is classified V.0: when the fire extinguishes in 10 seconds. According to U.L. 94 (Vertical Burning) the material is classified V.1: when the fire is extinguished in 30 seconds without dripping. According to U.L. 94 (Vertical Burning) the material is classified V.2: when the fire is extinguished in 30 seconds with dripping. |